Lubricants for the glass industry are an essential element to optimize results and achieve higher-quality processes. The glass industry relies heavily on various processes to ensure quality and efficiency in its production. Among these processes, the use of lubricants plays a very important role, contributing to improving both the quality of the final product and the energy efficiency of operations.

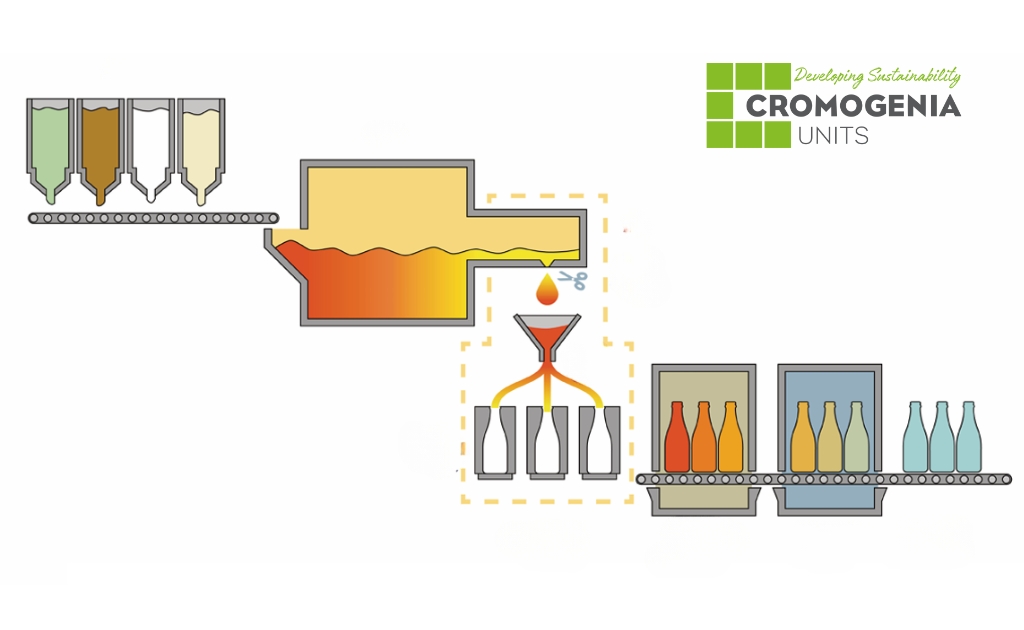

The hollow glass industry encompasses the manufacturing of bottles, jars, and glassware. In this sector, lubricants play a crucial role because this type of industry demands an exceptional level of efficiency and quality. In fact, the choice of appropriate lubricants can make the difference between standard production and an optimized manufacturing process.

The role of lubricants in the glass industry

Lubricants play a fundamental role in the glass industry by reducing friction and wear on the equipment and machinery used in the manufacturing processes. This not only extends the lifespan of IS machines but also enhances their performance, reduces dosing equipment clogging, consequently preventing downtime while minimizing defects in the final bottles.

Cromogenia Units, a leader in chemical solutions, develops a range of lubricants for the hollow glass sector, specifically designed for its production, standing out for their ability to improve product quality.

The lubricant enhances the quality of the glass

In the glass industry, the action of high-quality lubricants, such as those developed by Cromogenia Units, not only benefits the machinery but also influences the outcome of the final product. By reducing friction between materials and surfaces in contact during the shaping process, Cromogenia Units’ lubricants minimize the risk of surface defects, such as marks, which could negatively impact the appearance of the final product. This translates into faster and more consistent production, with fewer interruptions and downtime. It also results in higher-quality and more sustainable glass that meets the industry’s most stringent standards.

Lubricants and Energy Efficiency

Energy efficiency is another area where Cromogenia lubricants offer significant benefits. By reducing friction, equipment operates more smoothly, decreasing the resistance to movement of parts and, therefore, requiring less energy for the glass shaping process. This not only leads to cost savings and increased operational efficiency but also contributes to a more sustainable approach to hollow glass production..

Versatility and Effectiveness in Hollow Glass Production

In the production of hollow glass, such as bottles and containers, lubrication plays a crucial role in glass forming and molding. To enhance efficiency, lubricants must adapt to different machinery configurations and manufacturing processes. Cromogenia Units’ lubricants are specially formulated to provide the versatility and effectiveness required in these processes, ensuring the quality and uniformity of the produced glass. Whether in high-speed production lines or more specialized environments, these lubricants demonstrate their effectiveness, delivering consistent results and improving productivity in various hollow glass manufacturing scenarios.

For more information about our lubricants for the glass industry, feel free to get in touch with us. We are committed to providing high-quality lubrication solutions that enhance efficiency and productivity in your company.

Need more details about lubricants for the glass industry? Contact us here